|

Past Performance:

|

| ||||||

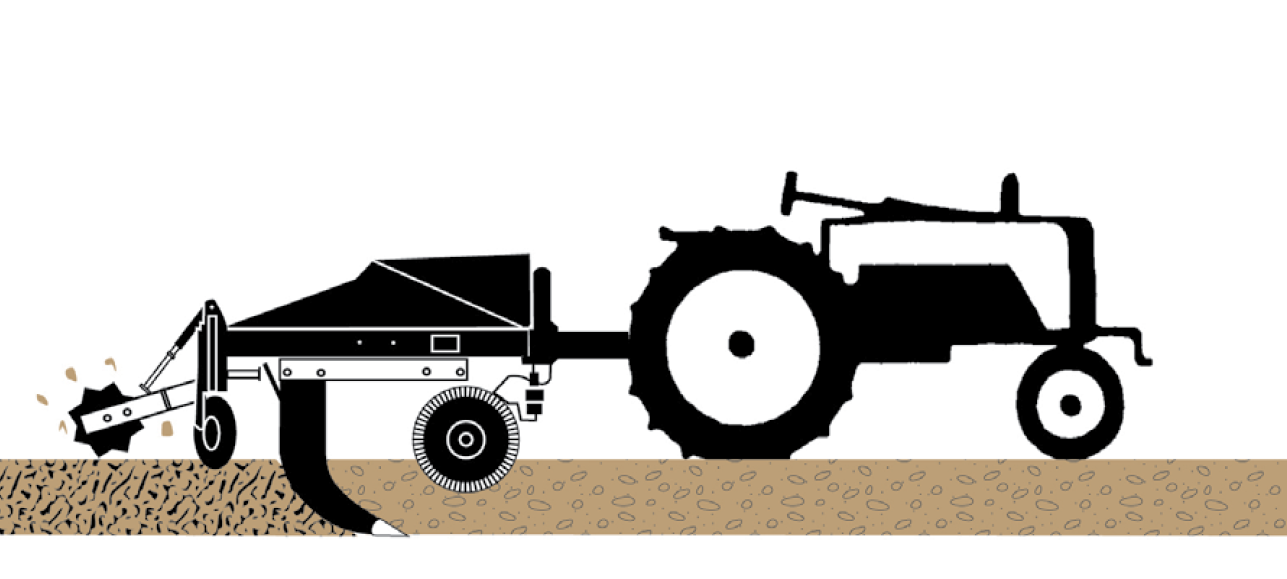

1. Prepare the Soil

Use tillers and disks to pulverize the soil to a depth of six inches of greater, preparing for the DuroEarth process.

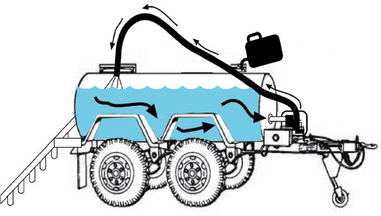

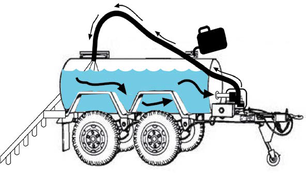

2. Apply enzyme solution

A water trailer or a truck outfitted with an adjustable spray bar will distribute the soil hardening enzyme solution.

3. Mix the soil

Once saturated, the enzyme is mixed thoroughly into the soil using a tiller of the TR3. Turning the soil over with a motor grader blade also provides excellent mixing.

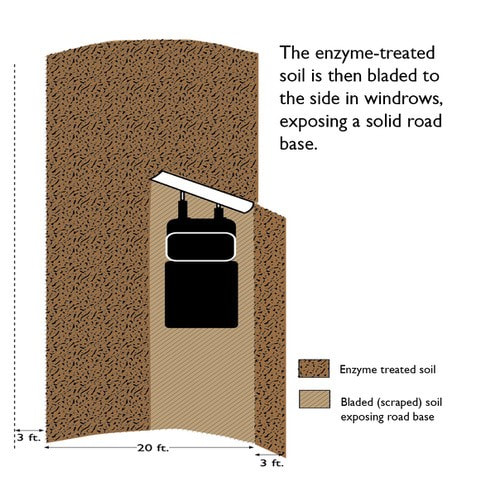

4. Create windrows

The enzyme-treated soil is then bladed to the side in windrows, exposing a solid road base. The treated soil is left to cure in the windrows for 24-48 hours. This process begins to dry and harden the soil.

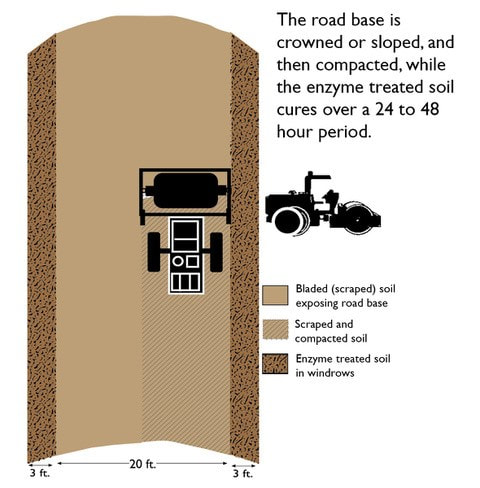

5. Crown the road base

The road base is crowned or sloped, and then compacted while the enzyme soil cures over a 24-48 hour period.

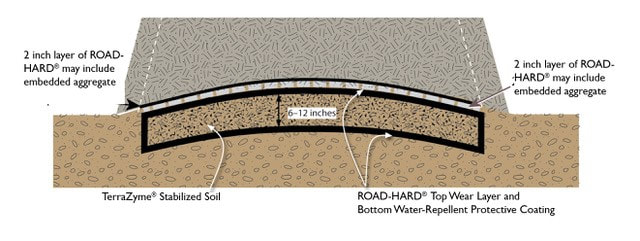

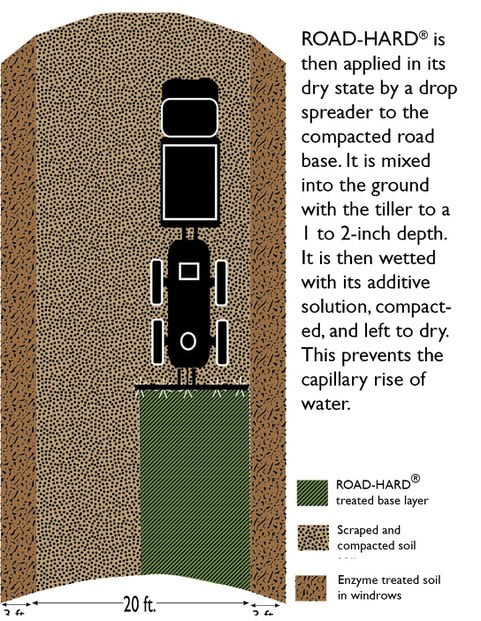

6. Apply ROAD-HARD

ROAD-HARD is applied in its dry state by a drop spreader to the compacted road base. It is mixed into the ground with the tiller to a 2-inch depth.

7. Apply ROAD-HARD additive

The ROAD-HARD Additive (not the enzyme) is then mixed and sprayed onto the ROAD-HARD covered base. This is then scarified, compacted, and left to dry. This prevents the capillary rise of water.

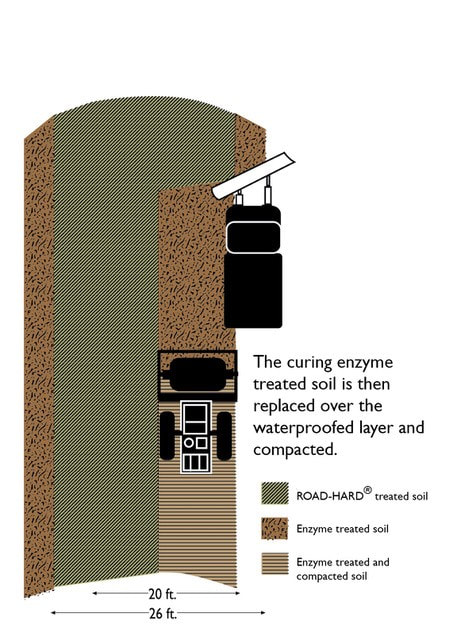

8. Replace windrowed soil

After 24 hours the curing enzyme treated soil is replaced over the waterproofed layer and compacted.

9. Final application of ROAD-HARD

The roadway and shoulders are treated with ROAD-HARD again (repeat step 6). This waterproofing solution encases the enzyme hardened soil in a water-resistant envelope.

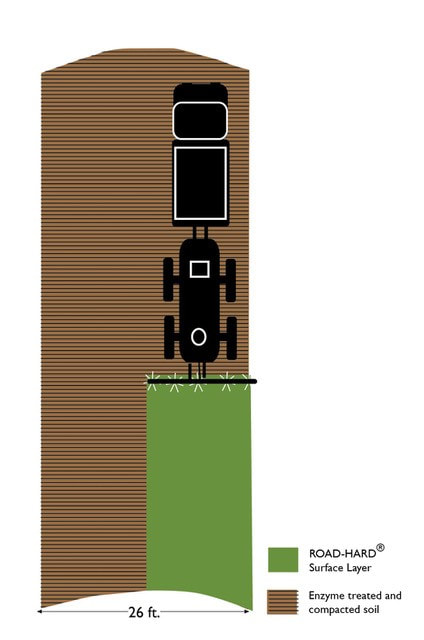

The DuroEarth process is a comprehensive method for building durable, water resistant roadways, runways, hardstands and berms. The patented process uses eco-friendly polymers and enzymes to harden soil and create a water-resistant "slab" of earth that is functional year round and resists erosion and supports traffic. This hardened slab is encased in a hydrophobic envelope of soil that prevents both the surface penetration and the capillary rise of water.

Contact us for quantity and pricing consultation at (703) 299-9575

ROAD-HARD and TerraZyme can be purchased on our store.

ROAD-HARD and TerraZyme can be purchased on our store.